Views: 0 Author: Site Editor Publish Time: 2022-03-02 Origin: Site

Section II Dismantle and Assemble of HW Series Transmission

Axle Assembly.

I. Dismantle of Axle Assembly (Supplementary Axle Needs not

Dismantle, Change the Supplementary Axle when it Repairing)

Figure 3-103 Figure 3-104

① Lift up the middle shell, and take off the main axle and fork axle. Punch the pins on

fork and fork block in turn by use punch nail (see Figure 3-103), and punch the pins

out of its position, and then finish the fork axle dismantle.

② Let the main axle in vertical condition, take off hex key, and turn the large barrier

chip of main axle. When the key groove aligns with the spline of main axle, the large

barrier chip, and reverse shift gear can be taken off. By this method, all the parts of

the main axle can be dismantled (see Figure 3-104).

③ Dismantle elastic barrier ring, input shaft bearing, spacer bush, gear elastic barrier

ring, one axle gear (reference the dismantle figure of input shaft in parts list). If only

changing the bearing of input shaft, the outside parts, such as separation bearing, oil

pipe, end cover of input shaft, stop ring, elastic barrier ring and others, only need to

be dismantled. Use special G08 to clamp the Snap ring groove of input shaft to

dismantle the bearing of input shaft (see Figure 3-105)

II. Axle Assembly Installation

1. Input shaft Assembly of HW19710 Series Transmission

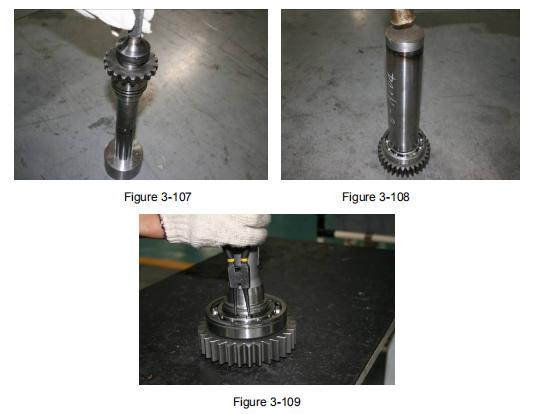

① Put elastic barrier ring for hole into one axle gear by circlip pliers (see Figure 3-106);

install input shaft bush into the inner hole of back end of input shaft and locating

(see Figure 3-107).

② Put clamp spring of one axle gear belt, spacer bush, rolling bearing (notice: outside

snap ring groove of rolling bearing directs to the front of transmission), onto the input

shaft, and use special tool G10 to install rolling bearing to its position (see Figure

3-108); put elastic barrier ring for axle use into the snap ring groove by circlip pliers,

and pay attention that there are more groups of barrier ring for axle use, and after

elastic barrier ring for axle is installed, it shall be ensured the distance between

elastic barrier ring for axle and bearing is less than 0.10mm (see Figure 3-109).

3. Main Axle Assembly installation of HW19710 Series Transmission

① Put 2 elastic column pins to the bottom of pin hole of main axle (see Figure 3-110);

put the elastic barrier ring for hole use into the clamp spring grooves of three-shift

gear, two-shift gear, one-shift gear, creep-shift gear and reverse shift gear (see

Figure 3-111) in turn by using circlip pliers.

② Let the main axle vertically stand, firstly put the large barrier chip onto the main axle

and turning the half gear (use wood plug to insert to prevent it running more); the

axle locating between gears is as Figure 3-112 shown: spline adjustable chip can

realize its locating by turning half gear and passing hex key (can use punch to adjust

the whole chip to drive the half gear running).Adjust the axle clearance between

gears, and the axle clearance of three-shift gear and two-shift gear, one-shift gear

and creep shift gear is o.15-0.35mm, and reverse gear to large barrier chip of main

axle is 0.30-0.50mm, its measuring method is as Figure 3-113 shown, the

measuring tool is clearance gauge, and pay attention that hex key shall have

installed 2 pieces.

4. Installation of Fork Axle

All kinds parts correspond positions of reverse shift fork axle assembly, one/two shift

fork axle assembly, three/four fork axle assembly, insert and split fork axle assembly

can take reference as explosive Figure of parts list shown. When installing pins of

fork axle or fork block, firstly put the pins in the symmetry position, then punch the

two ends of pins off, and pay attention to it shall be firm and stead to ensure that will

not loose during using period (see Figure 3-114).

Section III Dismantle and Assemble the Supplementary

Gearbox Assembly of HW Series Transmission

I. Dismantle the Supplementary Gearbox Assembly

① Let the output flange upward, dismantle the large bolt, pressure plate (see Figure

3-115) and use special tool G16 to dismantle the output flange (see Figure 3-116).

② Dismantle cylinder of range shift, piston (see Figure 3-117), end cover of output

shaft (see Figure 3-118, it has 8 fastening bolts).

③ Dismantle 2 support pins of fork axle (see Figure 3-119, the two arrows direct place),

and dismantle the bolt connected the torque drive chip with back shell (see Figure

3-120).

④ After dismantling the back shell of transmission, use special tool G03 to dismantle

bearing of planet carrier (see Figure 3-121). Turn over the planet device and use

special tool G17 to dismantle worm gear of odometer, rolling bearing (see Figure

3-122).

⑤ Keep suitable clearance between high shift cone-hub and synchronizing gear seat,

and use special tool G04 to dismantle high shift cone-hub (see Figure 3-123) and

take off the synchronizing ring; lift up synchronizing slip bush by two hands, and pay

attention to not lose and scattered ejector pad, inner and outside springs (see Figure

3-124).

⑥ Use circlip pliers to take off the elastic barrier ring clamped in the carrier of gear ring

(see Figure 3-125); use special tool G04 as Figure 3-123 shown to clamp the under

part of synchronizing ring (see Figure 3-126) and dismantle the synchronizing gear

seat, synchronizing ring and low shift cone-hub assembly.

⑦ Dismantle snap ring, bearing in the carrier of gear ring, and take off steel wire barrier

ring, inner gear ring (see Figure 3-127); the rest parts of planet carrier, input shaft

and inner sun wheel, planet wheel, washer and others need not to dismantle as a

entire, called planet device assembly (see Figure 3-128), and change it by a part

when repairing.

We are the agency for SINOTRUK wholesale truck series, we can supply HOWO tractor trucks, HOWO dump trucks, trailer truck, truck parts, agricultural machinery, Construction machinery and parts,HOWO concrete mixer trucks, special trucks and so on.we can supply trucks for our clients with good quality and competitive price, because we get directly support from the CNHTC factory.

Main products

1. Dump Truck / Tipper Truck

2. Hohan tractor Truck/ prime mover truck

3. Truck with crane / Truck mounted crane

4. Oil Tank Truck / Fuel Tanker Truck

5. Water truck / Water Tank Truck / Water Sprinkler Truck

6. Concrete Mixer Truck

7. Van truck / Insulated truck/ Refrigeration truck

8. Fecal suction truck / Sewage suction truck

9. Cement Powder Tank truck/ Bulk cement trailer

10. High-altitude operation truck

11.Semi Trailer ( flat bed trailer / skeleton trailer / dump trailer / side wall trailer / low bed trailer / container trailer, etc. )